This question was asked of me the other day and I abruptly said 20 years of practice and experience. Of course in reality that is less than half the time I have spent building the skill set i have today .

Thinking back on this question I decided it might be interesting, even to me, to list the steps (with photos) and see just how much time it takes me today to make a ring.

An issue of course is what ring construction should I follow? I make many types of rings but one of my favourites is a yellow Cedar Burl with a clear or coloured liner. Lets follow the process for that ring. Below is a photo of the larger of the pieces of Yellow Cedar burl I was given. It does take some effort and a good pressure washer to get most of the bark and dirt out of the nooks and crannies!

Step 1: Finding a piece of this wood is like trying to find Hen’s Teeth! I’m lucky as I was given a nice piece from Vancouver Island. Here is a photo the small piece I have saved for something special. Time: unknown

Step 2: Determining how best to cut the burl to maximize the usage and get the most beautiful piece from it. Time: with a large burl to decide would likely take at least 30 min. Then I would probably have to make the first cuts with a chain saw so lets say a total of 1 hour.

Step 3: Slice a piece of the Burl with the bandsaw. Time 1 minute

Step 4: Drill ring blank with hole saw. Time 2 minutes

Step 5: Dry ring blank in Toaster Oven. Time 6 to 12 hours depending on how wet the burl is.

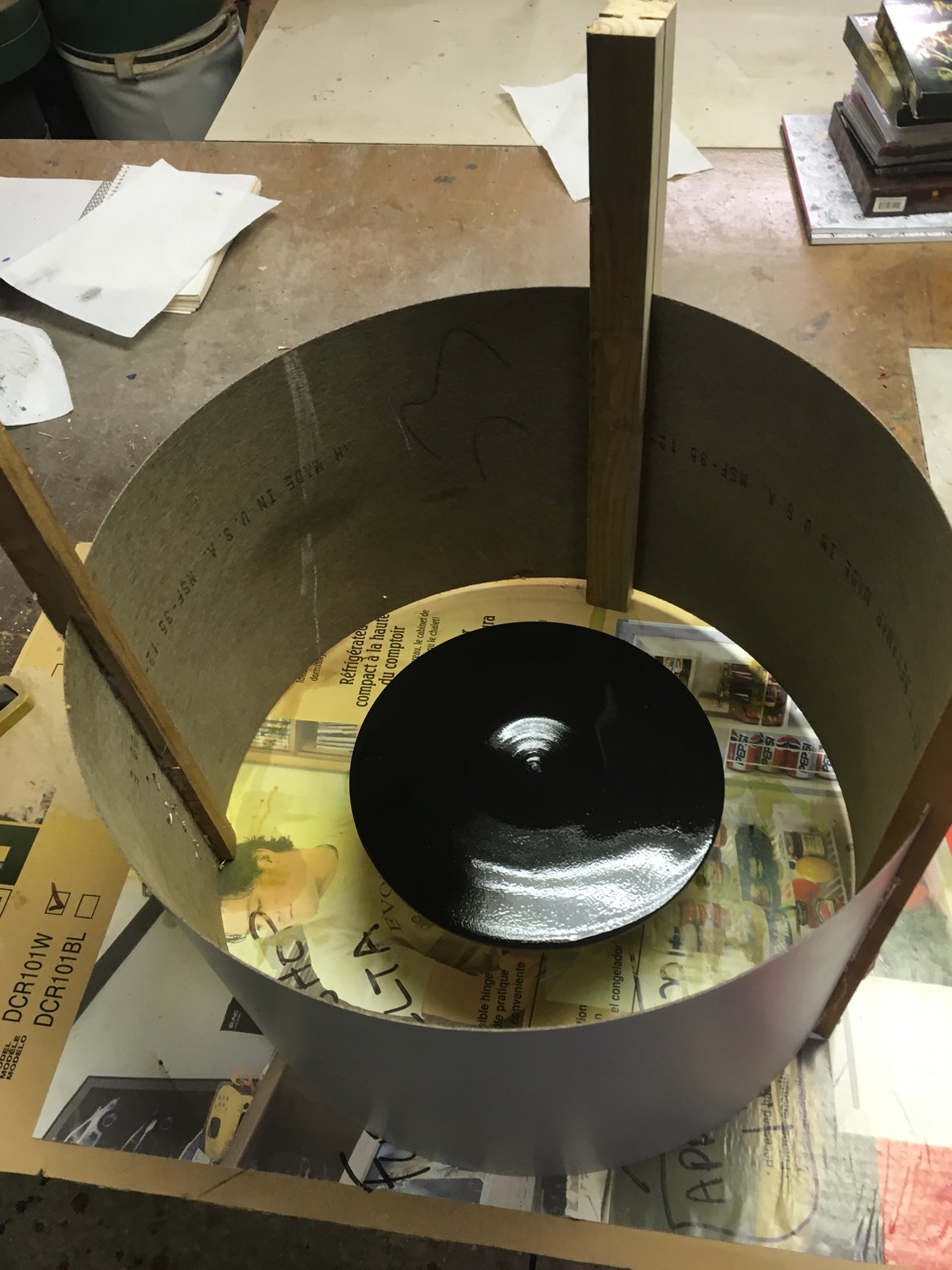

Step 6: Stabilize the ring blank in Cactus Juice in a vacuum pot. Time 30 minutes

Step 7: Bake the ring blank in in toaster Oven. Time 30 minutes

Step 8: Make liner. Time 10 minutes (to do this I must use just about all the steps to make a ring)

Step 9: Using jig in wood lathe, drill the blank close to ring size, must drill from both sides to minimize chipping out the back of the blank. Time 2 minutes

Step 10: Utilizing a boring head fit the inside of the blank to the ring liner. Time 2 minutes

Step 11: Glue the liner into the ring blank. I use med CA Glue. Time 1 minute

Step 12: Return the ring to the jig on the lathe and turn to final width, finish the inside corners and sand inside ring and corners. This requires the ring to be turned once in the jig. Time 4 minutes

Step 13: Finish the inside and inside corners with thin CA glue. I usually do 3 coats per side. This again requires the ring to be turned once in the jig. Time 2 minutes.

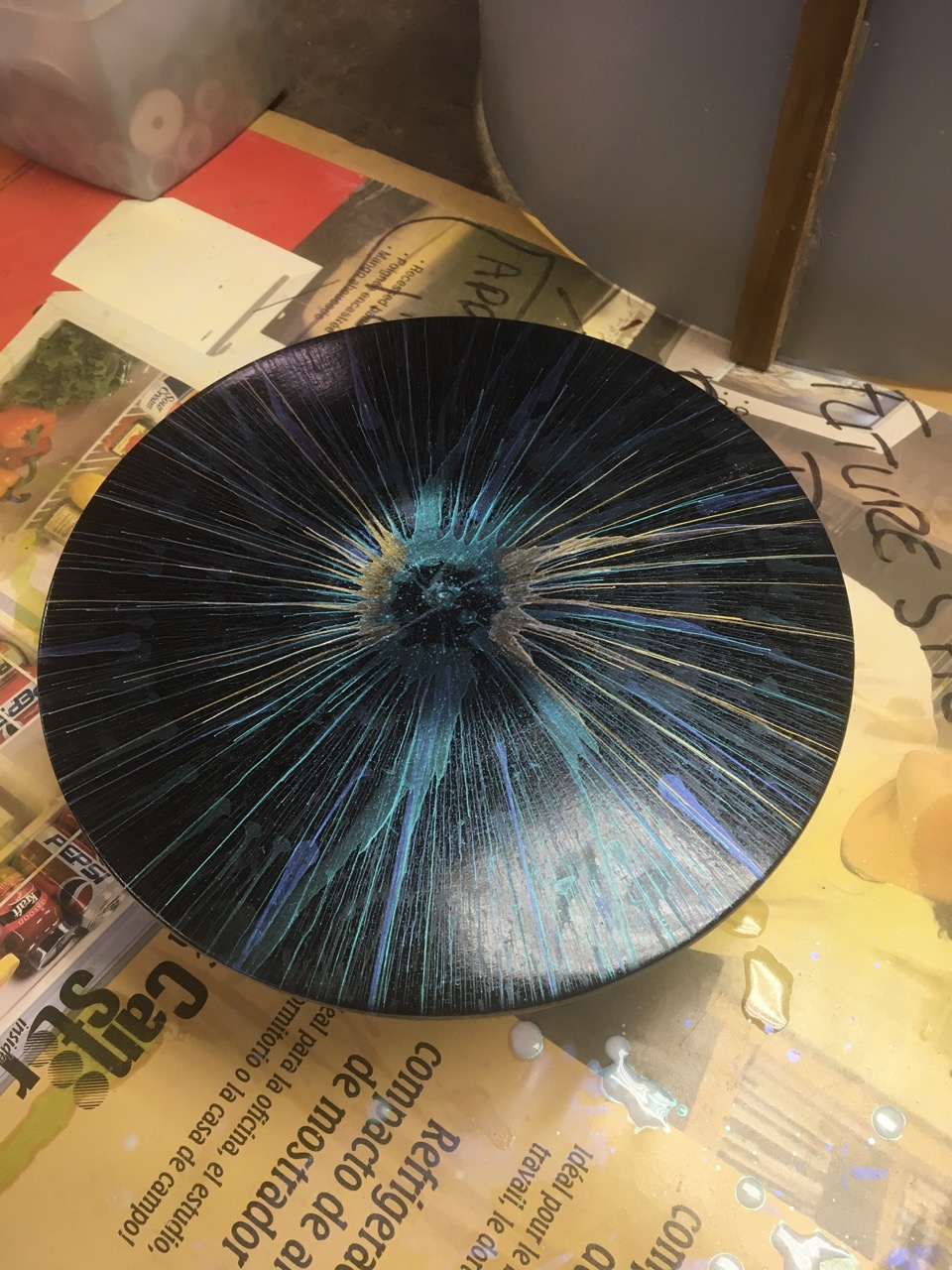

Step 14: Put ring on the home made ring mandrel to finish outside. Time 5 minutes.

Step 15: Apply thin CA glue to outside of ring (3 coats). Time 2 minutes

Step 16: Buff the ring, inside and out. Time 1 minute

Now thinking back on the original question I really can’t say actually how long it takes to make a ring and like most things that I enjoy doing I really don’t care!!

Hopefully you might find a snippet of information hidden in this text that might help you along the way to making finger rings.